home

introduction

build

sva tests

links

latest updates

Reverse mechanism

- February 10 -

STM do a nice reverse mechanism for the Phoenix, which means I won't have to faff around designing and building my own. It's a bike starter motor, mounted to the engine, and it engages in a sprocket that's attached to the output flange of the engine.

Collection time

- April 30 -

The reverse mechanism is nearly ready - Ian picked it up from his machinist whilst we were loading up the van, but when he inspected it, it was missing a little indent that allows it to fully retract into its bracket, so he kept it and will send it on later. He looked baffled when I started talking about ways to wire it up safely, so that it can't be engaged whilst the car is in any other state than idling in neutral. It turned out that my assumption from initial inspection that it was a Bendix type was wrong - it's pulled into place with a lever, and then activated. You'd have to be a muppet to do that accidentally!

Fitting the electric reverse

- September 3 -

Not much to do here except bolt it on. The bracket Ian supplies is, I think, a Fireblade one, with a couple of extra mounting holes in it to mount it on the GSX-R 1000. As such, the bracket has a couple of huge arms sticking out which aren't necessary. I've left them on for now, in case I find them useful for bolting something else to.

Well actually, I did have to slot one of the holes a bit, as one of them had been drilled 1mm out. There's no way to tell which one is the wrong one, of course, so let's hope I got the right one to slot, else the reverse won't engage properly in the ring gear when the time comes...

Connecting up the electric reverse

- December 30 -

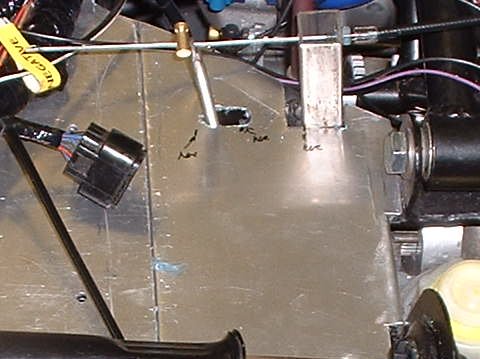

A little while ago I drilled a hole in the pedal box so that I could screw an M6 threaded rod into slide mechanism of the electric reverse. Now was the time to do something with it. A couple of hours, 2 rod-end bearings, some more studding and a bit of welding later, I ended up with this.

The verticalish bit of studding has a tab welded into the end of it, and through this is the inner of a standard locking choke cable. The outer of the cable reacts against a turret that I welded in for just that purpose. I've also put a standard bicycle gear adjusting ferrule on the outer to allow me dial out any slack that builds up as the cable stretches over time.

The slide mechanism itself is a bit rubbish, and binds as it moves, and the built in spring isn't powerful enough to overcome the friction. I tried lubricating the slide with some graphite, but it didn't help much, so I'm going to have to fit a helper spring to pull the slider back into place.

This page last updated on: Sunday, Jul 16 2006

Date

aeroscreen

body

boot

brakes

chassis

cooling

clutch

dashboard

electrics

emissions

engine

exhaust

final drive

fuel system

gear shift

lubrication

mirrors

panelling

propshaft

reverse

seats

steering

suspension

throttle

trim

wheels

garage